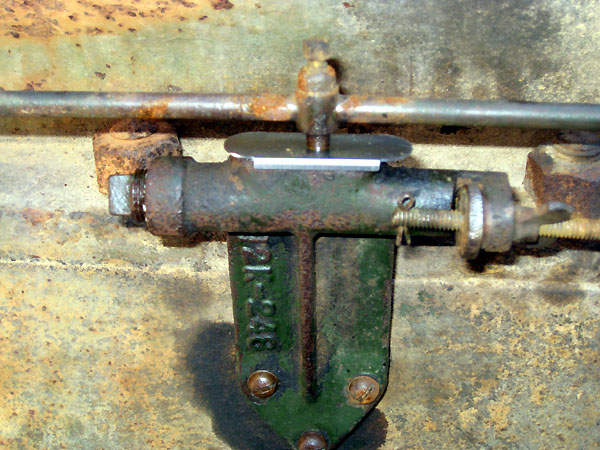

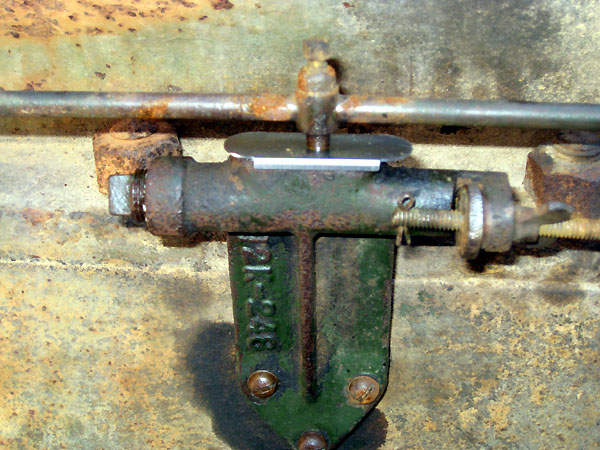

Model K Dashpot

The dashpot was an interesting feature and one

was fitted to all sizes of model K engines. It was basically a

small hydraulic brake consisting of a small cylinder capped at one end

with a pipe plug. In this cylinder was fitted a free sliding

piston. A pin extending down from the throttle rod fit into a

cross hole drilled in the piston. The dashpot was to be filled

with kerosene. A small steel cover helped keep water and debris

from jamming the piston. The fluid resistance helped steady the

throttle rod, preventing surging and sudden drastic changes in speed.

A tab on the rear of the dashpot also held the speed adjusting spring.

Because it is directly connected to the throttle rod the dashpot must be adjusted properly and kept working freely. The pin located on the throttle rod should be adjusted so that it does not strike the dashpot casting in the throttle's extreme open or closed position. The pipe plug is another area where caution is advised. The backside of the casting is very thin here and easily cracked from over tightening. The threads are 3/8 NPT and it is advisable to chase them 3/8 NPTS (straight pipe thread) and lighly install the plug with a suitable sealant such as Loctite® 545.

Entry of water into the dashpot can cause the piston to become seized, and serious damage can occur if the water is allowed to freeze. It is always advisable to manually check the throttle rod for free movement before starting the engine. The steel cover should always be in place to prevent entry of water and debris. The dashpot was intended to be filled with kerosene however any suitable non freezing or corrosive liquid may be used, WD-40 being one such example. More viscous fluids such as brake fluid, transmission oil or motor oil will cause improper operation and should never be used.

On late 3 and 5hp model KA engines having the fuel fill on governor side also had the dashpot deleted. Apparently F&J decided it was not necessary after all with these sizes. They also did not include one on the NK series.

The dashpot seen here on a 12hp engine

Because it is directly connected to the throttle rod the dashpot must be adjusted properly and kept working freely. The pin located on the throttle rod should be adjusted so that it does not strike the dashpot casting in the throttle's extreme open or closed position. The pipe plug is another area where caution is advised. The backside of the casting is very thin here and easily cracked from over tightening. The threads are 3/8 NPT and it is advisable to chase them 3/8 NPTS (straight pipe thread) and lighly install the plug with a suitable sealant such as Loctite® 545.

Entry of water into the dashpot can cause the piston to become seized, and serious damage can occur if the water is allowed to freeze. It is always advisable to manually check the throttle rod for free movement before starting the engine. The steel cover should always be in place to prevent entry of water and debris. The dashpot was intended to be filled with kerosene however any suitable non freezing or corrosive liquid may be used, WD-40 being one such example. More viscous fluids such as brake fluid, transmission oil or motor oil will cause improper operation and should never be used.

On late 3 and 5hp model KA engines having the fuel fill on governor side also had the dashpot deleted. Apparently F&J decided it was not necessary after all with these sizes. They also did not include one on the NK series.

The dashpot seen here on a 12hp engine

9hp and up model K engines had a secondary dashpot

located on their intake valves. This consisted of a

small cast cylinder that screwed to the head over the valve

assembly. The vale keeper was a two piece riveted

assembly made so as to have a groove around its midsection,

much like a piston ring groove. A bronze piston ring

was fitted to the groove and this provided slight tension

against the cast cylinder's bore. The cylinder had a

small boss cast on its top side which was tapped for a brass

petcock. Opening or closing the petcock caused

resistance to be put on the intake valve due to slight air

compression as the admission valve as sucked inwards.

Inner surfaces of the cylinder as well as the bronze rings

should be lightly coated with a thin oil such as machine

tool spindle oil upon assembly. It should not be

filled with any quantity of oil and checked daily for free

movement.